Movement, Watch Case, Hands

Movement.

Movement is the internal mechanism of a clock or watch, as opposed to the case,

which encloses and protects the movement, and the face which displays the time.

Going Barrel Gear (large) --> Center Wheel Pinion (small) --> Center Wheel (large) -->

Third Wheel Pinion (small) --> Third Wheel (large) --> Fourth Wheel Pinion (small) -->

Fourth Wheel (large) --> Escape Wheel Pinion (small).

Mechanical Watch.

The internal mechanism of a watch, excluding the face and hands, is called the Movement.

All mechanical watches have these five parts.The mechanical watch is the mature technology, and virtually all ordinary movements have the same parts and work at the same way.

It is like the engine of the automobile, just few car makers can produce high-end V-12 engine.

1. Main Spring

2. Gear Train

3. Balance Wheel

4. Escapement

5. An Indicating Dial

Going Barrel / Main Spring / Power Source.

Energy created by winding would store inside this barrel by the main spring, as the energy

was released, it's transferred to the second gear called the gear train. The winding

mechanism must always have a " Ratchet " attached, with a " Pawl " to prevent the spring

from unwinding.

The mainspring is coiled around an axle called the " Arbor ", with the inner end hooked to it. In many clocks, the outer end is attached to a stationary post. The spring is wound up by turning the arbor, and after winding its force turns the arbor the other way to run the clock.

" Going Barrel " the form used in modern watches, is wound by turning the arbor and drives

the watch movement by a ring of teeth around the barrel. This enables the mainspring to continue running the watch while it is being wound. The mainspring is coiled around an arbor and enclosed inside a cylindrical box called the barrel which is free to turn. The spring is attached to the arbor at its inner end, and to the barrel at its outer end. The attachments are small hooks or tabs, which the spring is hooked to by square holes in its ends, so it can be easily replaced. Invented by Jean - Antoine Lepine

The mainspring is wound by turning the arbor, but drives the watch movement by the barrel; this arrangement allows the spring to continue powering the watch while it is being wound. Winding the watch turns the arbor, which tightens the mainspring, wrapping it closer around the arbor.

The arbor has a ratchet attached to it, with a click to prevent the spring from turning the arbor backward and unwinding. After winding, the arbor is stationary and the pull of the mainspring turns the barrel, which has a ring of gear teeth around it. This meshes with one of the clocks gears, usually the " Center Wheel Pinion " and drives the " Wheel Train ".

From right to left, Center Wheel, Third Wheel, Fourth Wheel, Escape Wheel.

The gear train which transferred the force of the main spring to the balance and adding

up the swings of the balance wheel to get units of seconds, minutes, and hours.The large

gear in timepiece are generally called " Wheel ", the small gear they mesh with (large to small)

are called " Pinion ".

The going train has two functions. First, it scales up the speed of rotation of the mainspring or weight pulley. This allows the use of a very strong, slow turning mainspring or heavy weight that will run the timepiece for days or weeks.

Second, its gear ratio divide the rotation of the escape wheel into convenient time units of seconds, minutes, and hours, to turn the timepiece's hands. The going train wheels are the only ones under load in a timepiece, since they bear the constant torque of the mainspring which is applied to the escapement, so these wheels are the only ones that receive significant wear.

Center Wheel :

Center turns once per hour. Its pinion is turned by the teeth on the " Main Spring " in watches and spring driven clocks, and by the weight pulley in weight driven clocks. It also drives the pinion of the third wheel. Its arbor projects through a hole in the face and drives, via a friction coupling the " Cannon Opinion ", which carries the " Minute Hand ".

Third Wheel :

Third wheel drives the pinion of the fourth wheel. (this is called the third wheel because the mainspring barrel is the first wheel and the center wheel is the second wheel in the gear train).

Fourth Wheel :

In clocks and watches with the second hand in a subdial on the face, this turns once per minute, and the shaft projects through the face and holds the " Second Hand ". The fourth wheel also turns the escape wheel pinion. Many clocks don't need this wheel, because of their slower moving escapements, and in these the third wheel drives the escape wheel directly.

Escape Wheel :

This wheel is released one tooth at a time by the " Escapement ", with each swing of the pendulum or balance wheel. The escape wheel keeps the pendulum or balance swinging by giving it a small push each time it moves forward.

Escape Wheel, Pallet Fork, Balance Wheel, and Hairspring form the Escapement.

Hairspring oscillates the and Balance Wheel swings as the result they divided the time.

Balance Wheel.

The balance wheel is the timekeeping device used in mechanical watches and some clocks,

analogous to the pendulum in a pendulum clock. It is a weighted wheel that rotates back and forth, being returned toward its center position by a spiral spring, the balance spring or hairspring. It is driven by the escapement, which transforms the rotating motion of the watch gear train into impulses delivered to the balance wheel.

Each swing of the wheel (called a 'tick' or 'beat') allows the gear train to advance a set amount,

moving the hands forward. The combination of the mass of the balance wheel and the elasticity of the spring keep the time between each oscillation or ‘tick’ very constant, accounting for

its near universal use as the timekeeper in mechanical watches to the present. From its invention in the 14th century until quartz movements became available in the 1970s, virtually every portable timekeeping device used some form of balance wheel.

Balance Spring / Hairspring.

requirement, so it has lot of training and experience.

A jewel bearing is a plain bearing in which a metal spindle turns in a jewel-lined pivot hole.

The hole is typically shaped like a torus and is slightly larger than the shaft diameter.

The jewel material is usually some form of synthetic sapphire, such as ruby.

The advantages of jewel bearings include high accuracy, very small size and weight, low and predictable friction, including good temperature stability, and the ability to operate without lubrication and in corrosive environments. They are known for their low static friction and

highly consistent dynamic friction.

Sapphire surfaces are very hard and durable, with Mohs hardness of 9 and Knoop hardness

of 2000, and can maintain smoothness over decades of use, thus reducing friction variability.

Disadvantages include brittleness and fragility, limited availability/applicability in medium and large bearing sizes and capacities, and friction variations if the load is not axial.

This type of donut-shaped bearing (red) is called a hole jewel, used for most of the ordinary wheels in the gear train. It is usually made of synthetic sapphire (ruby), press-fitted into a hole in the movement's supporting plate (grey). The cup-shaped depression in the top of the jewel is the oil cup; its purpose is to hold the lubricating oil (yellow) in contact with the bearing shaft by capillary action.

The worker adjusts the timing by controlling the hairspring.

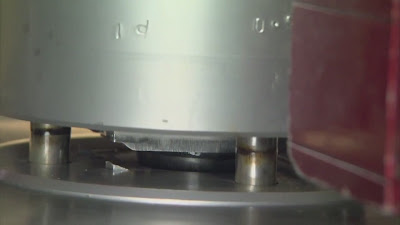

The Case Process.

The casing starts from the stainless steel bar.

The basic shape of the case has been formed.

Put the case into the oven to melt the special metal together.

Polishing.

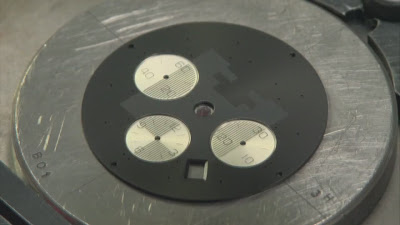

Dial Process.

Fastener Pin

After galvanizing process, the surface is shiny, instead of matte.

The gun is golden, due to its precision.

Stamp the hand.

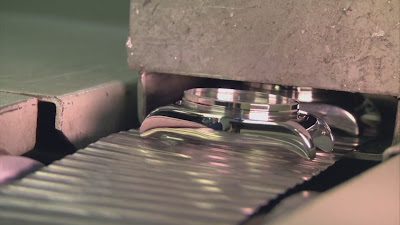

Bracelet

Polishing.

The white paste is more abrasive for basic surface, the orange paste is for the finished

process, it is more softer and finer.

Bracelet come together.

Bentley Continental GT

I dream to own Rolex for Rolls Royce Phantom.

Just Go Around The World with Hoff Production !

Terminology :

Balance Spring (Hairspring), Balance Wheel, Escapement, Jewel Bearing, Mainspring, Mechanical Watch, Movement (clockwork), Wheel Train (horology),

Reference :

1. Wikipedia : Balance Wheel, Jewel Bearing, Mechanical Watch, Wheel Train (Horology),

2. Mechanical Clock, Mechanical Watch Structure and Theory.

No comments:

Post a Comment