Victorinox : On the Cutting Edge - Swiss Style Magazine.

What an extraordinary scene ! Swiss is the beautiful country, but this is not Tour Channel.

The contents also excerpted from : Swiss Style - The Swiss Magazine for Leaders.

For more information : On the Cutting Edge

Victorinox Milestones

1884 — Karl Elsener opens his cutlery business in Ibach-Schwyz.

1891 — The Swiss Army is supplied with soldiers’ knives for the first time. 1

1909 — In order to distinguish it from copies, the company founder decides to use the cross and shield, the current Victorinox emblem, on all pocket knives

from then on.

1945 — After the Second World War, the PX stores of the U.S. Army, Marines and Air Force sell large numbers of the “Swiss Officer’s Knife” to their officers and soldiers. The Ameri cans call it “Swiss Army Knife” for short. This term is adopted in all English-speaking countries.

1989 — Expansion into timepieces

1999 — Victorinox strengthens the brand and broadens its appeal with the Travel Gear line.

2000 — Establishment of the Victorinox Foundation to provide job security in the long term and to ensure financial independence.

2001 — All five Victorinox product categories (pocket tools, household and professional knives, timepieces, travel gear and fashion) are presented for the first time together in a flagship store in Soho, New York.

2005 — Takeover of Wenger SA, Delémont (CH), a knife manufacturer since 1893 and also a supplier to the Swiss Army.

2008 — First European f lagship store in New Bond Street, London.

2009 — Victorinox has a global workforce of over 1,700 and generates sales of about CHF 500 million.

mass produced.

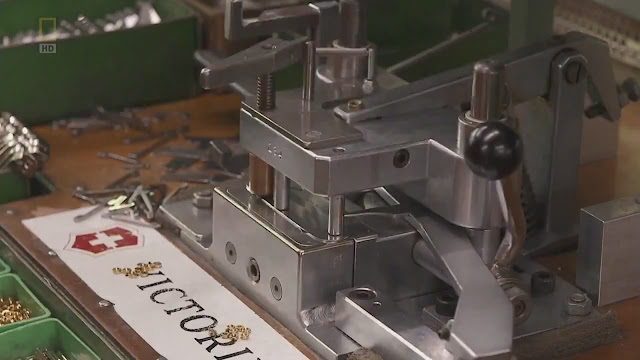

Let's see how to manufacture the blade.

Mold. It is like the stamping process in the automobile industry.

After stamping process, the amber hose uses the air to blow the blade away from the mold.

Depend on the different mold, the machine can produce variable blades.

When the metal meet the ceramic stone.

This process takes from 5 to 8 hours.

the residue from the stamping process.

Hardening.

The raw steel is too soft to cut anything. This oven solidify the steel, 1050 degrees changed

the molecular structure of the metal. The key element to steel is the carbon, too much carbon

would be brittle, so they need to balance flexibility and hardness.

After stamping, polishing, and hardening, it is time to grind. Grinding the surface to the right

dimension.

dimension. The water lubricates the blade and prevents the heat to build up.

The micrometer checks the exact dimension.

obvious and visible consequence was a drastic change in air travel regulations to prevent

that planes could ever be used as potential weapons again.But 9/11 and the radical change of airlines regulations that followed also made collateral victims thousands of kilometres away from the US.

As airlines forbade to carry knives on board, Victorinox, for which the US was the most important market, witnessed an almost overnight decline of 30 percent in its turnover. Business to business sales also decreased sharply, as Swiss Army knives were now perceived as an inappropriate gift in the US – the terrorists had used simple box cutters to hijack the planes.

“Watches helped to compensate the drop a little bit, but it was indeed a very difficult time,” admits Carl Elsener in his usual even tone, which does not give away the number of sleepless nights one assumes the Elseners must have gone through trying to find ways of saving their business. This task was even made more complex by the Elseners’ resolute decision not to let one person working for their company go.

Let's see how to manufacture the classic red handle.

Swiss Army Knife has broken my record of the pictures.

Thank Maybach, all photographs Swiss Army Knife is very informative, especially for me and generally for all Maybach readers around the world. Why do I say this? This is not because if this information is in video form as in Megafactories or Youtube, it took some time to watch it so that everyone understood and memorized exactly how the mass production process of a company called Victorinox (and also Wenger, who has been bought by Victorinox some time ago).

ReplyDeleteThank you,

My compliments,

Ahmad Said Widodo

from Purwakarta, West Java, Indonesia.

9/11 Military Grade Dagger is a fixed-blade and futuristic knife. It is considered as an outdoor combat and tactical knife/dagger that is requisite for any crisis or danger situation.

ReplyDeleteDue to its comfortable manufacturing design, this dagger can equip easily in your hand

A quality knife should be handy and accessible, as well as a firm grasp to perform the function properly.

An additional advantage is that, you can utilize this dagger as an easy-duty hammer or glass-breaker for emergency situations.

The blade is thermally treated in an expert manner to make it firm and solidify further. This feature makes it more rigid as well as increases the proficiency of the knife.https://fmtacticalgears.pk<>9/11 Military Grade Dagger